Launching Engineering Futures with ENABL's Consulting Internship Program

Praised by Aarhus University and students, this program highlights ENABL as a highly attractive workplace for aspiring engineers

Offshore wind in the US will soon face a challenge with the logistics of the WTG components, as the installation method from the EU and the rest of the world cannot be used in the US due to The Jones Act.

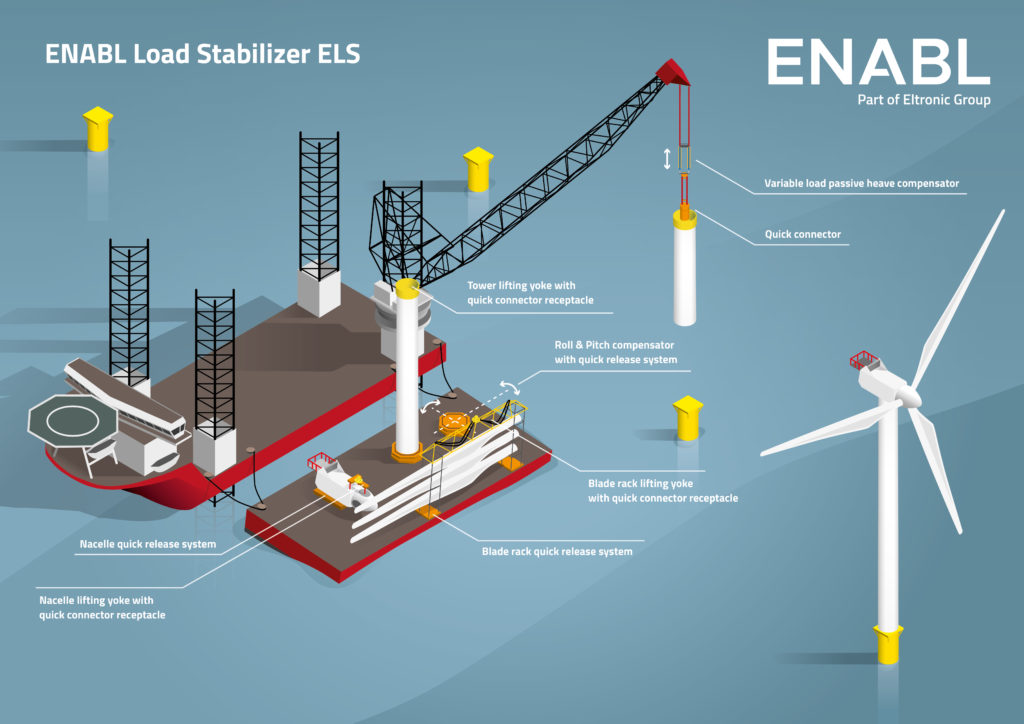

Eltronic Wind Solutions A/S (now part of ENABL A/S) and FORCE Technology have developed the solution, ENABL Load Stabilizer, for lifting offshore wind turbine generator (WTG) components from floating barge to jack-up vessel. This project will optimize the utilization of the costly jack-up vessels by reducing the time in port and in transit between port and installation site. With this solution it is also possible to comply with The Jones Act in the US. The project is supported by EUPD (Energy Technology Development and Demonstration Programme).

Offshore wind in the US will soon face a challenge with the logistics of the WTG components, as the installation method from the EU and the rest of the world cannot be used in the US due to The Jones Act. The Jones Act states that goods transported between US ports must be transported on vessels built, owned, and operated by US citizens. The number of Jones Act compliant installation ships on the way will not be able to keep up with the demand and there is a need for a feeder barge system where non-jones-act compliant installation ships can be utilized.

“ENABL has many years of experience in stabilizing offshore lifting and this combined with experience in developing lifting equipment for the wind industry and an innovative culture has enabled us to come up with a safe solution that is cost effective in both procurement, operation and maintenance. The solution is unique because it is based on passive systems that use a minimum of energy and at the same time can be operated in higher winds/waves than any other system on the market,” says Thomas Hedegaard.

The ENABL Load Stabilizer system is capable of operating sea states with significant wave heights of 2.5 meter. This is feasible due to a combination of a quick release clamp system and a variable load passive heave compensator. This ensures that the WTG component is lifted away from the barge without the risk of re-contact between the barge and WTG component. Furthermore, the crane and the WTG component is loaded in a safe and controlled manner without large dynamic impacts loads on the crane. The new solution is developed by using already well-known solutions in the offshore oil industry combined with new developments from ENABL to meet the requirements. Increased operation window for barge feeder system and reduced operation time for the reloading process will provide substantial benefits for the customers.

ENABL currently supplies Tagline Systems for load stabilization during installation of WTG and has a market share of approx. 90% in the world ex. China. The customers for ENABL Load Stabilizer system will be the same as for the Tagline Systems.

ENABL expects, that the technology will be the most used on the upcoming, planned US installations of 30GW.